주목 제품

Valves for ALD processes

High-speed, high-durability valves

The TDF Series includes valves for high purity gas, balancing the high-speed open/close, high durability, heat resistance, and Cv stability needed for ALD (atomic layer deposition) processes.

Features

High-speed open/close and high-response stability

Realizes valve response time of 18 ms* and response stability post-durability cycle of ±2 ms*.

*Performance values with KITZ SCT testing methods

Supports high-temperature fluids

With a structure reducing thermal conduction to the actuator, high-temperature fluids up to maximum 220°C* can be used.

*Up to 200°C with solenoid valves or sensors equipped

Stable Cv values

The use of a structure and seat material allowing for heat effects ensures Cv 0.5* at 220°C.

*Cv value initial error and fluctuation rate during use within ±5%

High durability

・ Our proprietary technology enables high-temperature fluids of 220°C and durability at 40 million cycles or more

・Achieves durability test performance values of 100 million cycles or more*.

*KITZ SCT test performance (test conditions) with fluid: N2, sealing pressure: 0.25 MPa (G), gas contact temperature: 220°C

Main specifications

For details, see the product catalog. Access is also available via the button below.

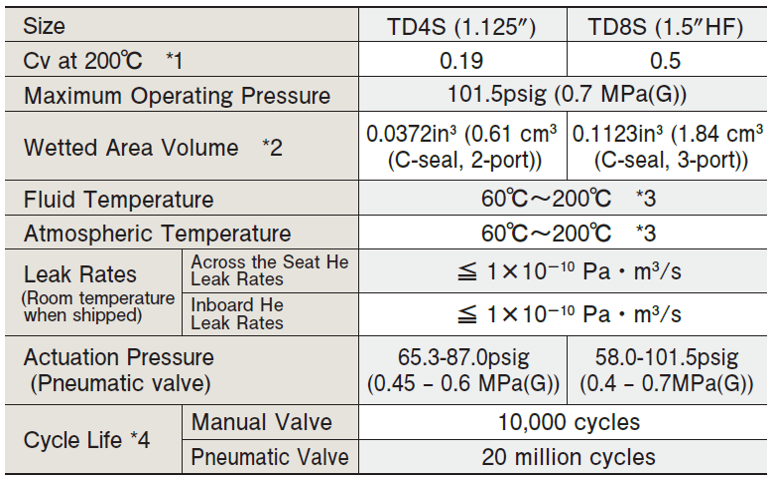

SCV submersible valves® TD-S Series

The SCV submersible valves® TD-S Series includes valves supporting integrated gas systems, usable in high-temperature environments through our unique technology. Suitable for precursor supply in ALD (atomic layer deposition) processes calling for flow rate reproducibility.

Submersible valves: Valves which can be used in high-temperature environments

*"SCV submersible valve" is a registered trade mark of the KITZ SCT CORPORATION.

Features

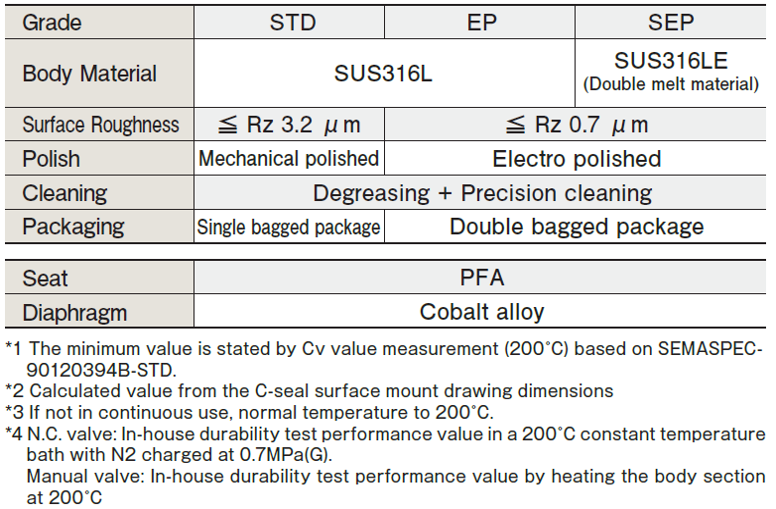

Supports high-temperature environments

Efficient heating is possible as the entire valve can be used in high-temperature environments up to a maximum of 200°C.

Stable Cv values

All valves' Cv values are adjusted at shipping. Low Cv value fluctuation rate during use enables stable gas flow rate.

Cv value initial error within ±5%, fluctuation rate during use within ±10%

Use of PFA seat

PFA, with excellent heat and corrosion resistance, is used. Usable with a wide variety of gases.

High durability

The use of a resin seat with performance values of 20 million cycles* improves durability, with regard to seat leaks, cycle life, and so on, compared to the metal seat type in high-temperature environments.

*Automatic valve KITZ SCT test performance (test conditions) with fluid: N2, sealing pressure: 0.7 MPa (G), ambient temperature: 200°C

Main specifications

For details, see the product catalog. Access is also available via the button below.

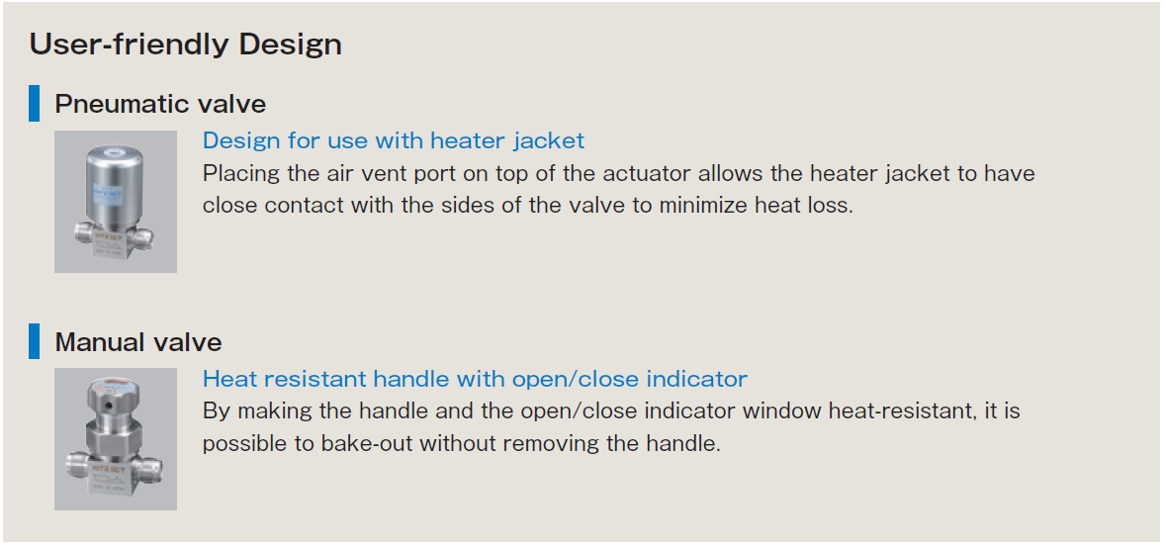

SCV submersible valves® KD-S Series

The SCV submersible valves® KD-S Series includes valves usable in high-temperature environments through our unique technology. Suitable for precursor supply in ALD (atomic layer deposition) processes calling for flow rate reproducibility.

Submersible valves: Valves which can be used in high-temperature environments

*"SCV submersible valve" is a registered trade mark of the KITZ SCT CORPORATION.

Features

Supports high-temperature environments

Efficient heating is possible as the entire valve can be used in high-temperature environments up to a maximum of 200°C.

Stable Cv values

All valves' Cv values are adjusted at shipping. Low Cv value fluctuation rate during use enables stable gas flow rate.

Cv value initial error within ±5%, fluctuation rate during use within ±10%

Use of PFA seat

PFA, with excellent heat and corrosion resistance, is used. Usable with a wide variety of gases.

High durability

Use of a resin seat with performance values of 5 million cycles* improves durability compared to metal seat type in high-temperature environments

Durability performance with regard to leaks, cycle life, and so on has been improved.

*Automatic valve KITZ SCT test performance (test conditions) with fluid: N2, sealing pressure: 0.7 MPa (G), ambient temperature: 200°C

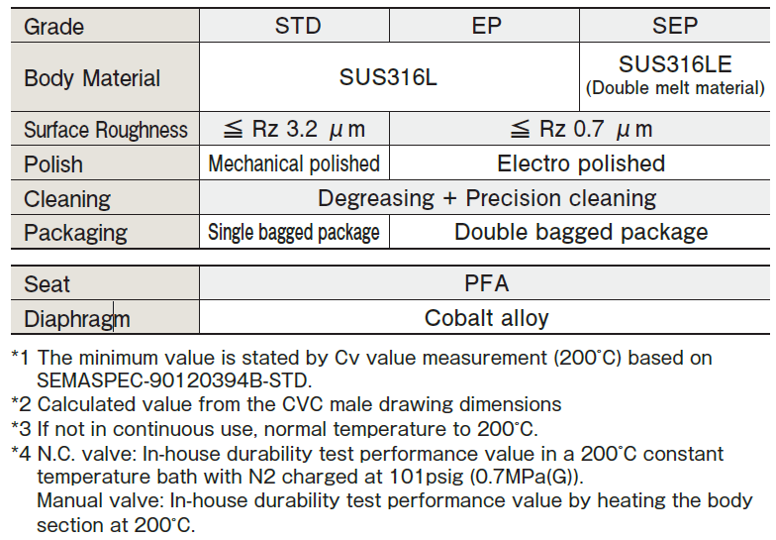

Main specifications

For details, see the product catalog. Access is also available via the button below.

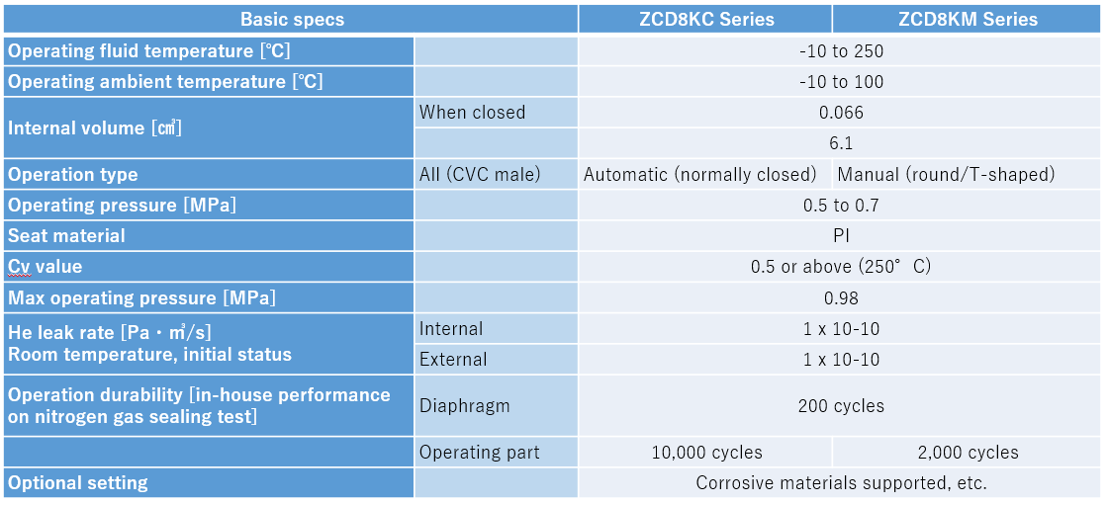

Zero volume valves supporting 250°C

The ZCD8K Series includes valves with replaceable seats, suited to use with 250°C high-temperature fluids through the use of our unique technology, in response to higher temperature needs for material container valves for next-generation memory media. Suitable for precursor supply in ALD (atomic layer deposition) processes which use low-vapor pressure solid materials.

Features

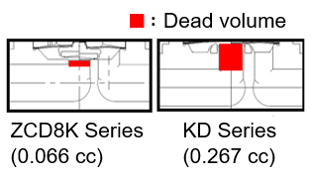

Reduction of dead volume

With valve closed, internal volume from seat to main flow path is reduced by about 75%, realizing superb gas replacement characteristics.

Gas contact parts support high temperatures of 250°C

With the use of a resin seat (PI: polyimide), operating fluid temperatures of 250°C are supported. (Max operating ambient temperature: 100°C)

Diaphragm vacuum blocking reduced

With our unique forced lift function technology used in the diaphragm, vacuum blocking is suppressed.

Seat and diaphragm can be replaced

Our proprietary diaphragm and seat assembly, with a centering function, enables easy replacement.

Main specifications

Contact our sales personnel for details. Inquiries can also be made via the button below.